Silicone Rubber Rollers & Molded Parts: Ready for Demanding Applications

When heat, pressure, and chemical exposure push materials to their limits, silicone rubber rollers and silicone molded parts hold the line. At Rol-Tec, we engineer high-performance silicone solutions that excel in coating, laminating, printing, packaging, and food processing—industries where precision and durability are non-negotiable.

Whether you need a custom roller covering or a molded component designed to withstand extreme conditions, Rol-Tec delivers tailored solutions with industry-leading precision.

Why Silicone? More Than Just Heat Resistance

Silicone’s reputation for high-temperature performance is well known, but its advantages go beyond that:

- Unmatched Release Properties – Silicone resists sticking, making it ideal for coating and laminating applications where clean separation is critical.

- Resilience Under Pressure – Unlike other elastomers, silicone maintains flexibility and shape under heavy loads.

- Chemical & UV Resistance – Designed to handle industrial solvents, oils, and prolonged sun exposure without breaking down.

- Enhanced Toughness – By blending silicone with EPDM and Hypalon, we improve its abrasion resistance while preserving its release and temperature resistance.

Silicone is a material engineered for longevity, and when formulated correctly, it outperforms standard rubber compounds in specialized industrial applications.

Silicone Rubber Rollers: Engineered for Precision & Longevity

Rol-Tec manufactures and refurbishes silicone rubber rollers for a wide range of industrial applications. Whether you need a new roller or a recovered one, we deliver:

- Custom durometers for specific pressure and friction needs

- Precision-ground surfaces for uniform application

- Dynamic balancing to reduce vibration and extend roller life

- Industry-specific coatings to enhance performance

Our rollers are built to endure intense production cycles, reducing downtime and maintaining consistent results over the long term.

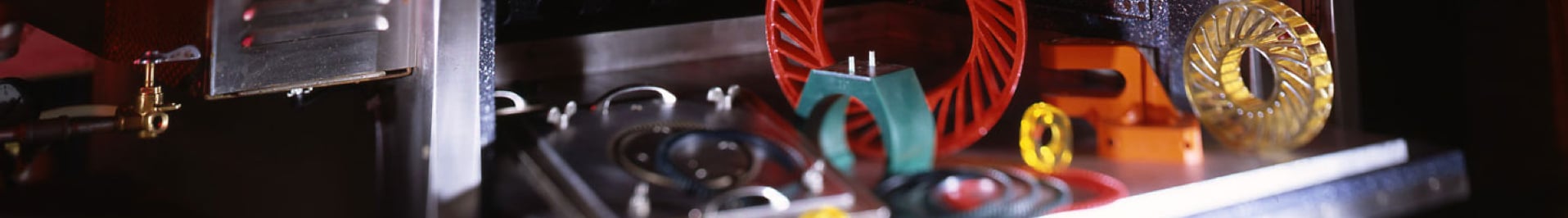

Silicone Molded Parts: Custom Solutions for Unique Challenges

From seals and gaskets to precision-molded sleeves, Rol-Tec’s silicone-molded parts meet exact industry demands. Our in-house molding process allows for full customization, ensuring that each part is formulated for the specific conditions it will face—whether that’s extreme heat, chemical exposure, or high-pressure environments.

Common applications include:

- Medical & Food Processing – FDA-grade silicone for sanitary, non-stick performance.

- Printing & Packaging – Precision-molded rollers and sleeves for smooth material transfer.

- Industrial Sealing Solutions – High-tolerance molded parts for gaskets and pressure seals.

Every component is engineered to fit your specs, built for durability, and manufactured with exacting precision.

Rubber Roller Re-covering: Restore Performance, Extend Life

Why replace a worn roller when you can recover it for a fraction of the cost? Rol-Tec’s rubber roller re-covering services breathe new life into damaged or worn-out rollers, restoring them to like-new condition with industry-leading precision.

- Re-covering vs. Replacing – Cost-effective, fast, and sustainable

- Tailored to Your Application – Choose from rubber, urethane, or silicone coverings

- Full Machining Capabilities – Handling rollers up to 31” OD x 280” between centers

If your rollers are showing wear, our recovery process will extend their performance and save you money.

Why Rol-Tec? The Difference is in the Details

At Rol-Tec, we do more than supply rollers and molded parts—we engineer performance solutions tailored to the most demanding industrial applications. Our fully integrated facility allows us to:

- Control every step of production, from raw material formulation to final finishing

- Customize silicone blends for enhanced durability, heat resistance, and release properties

- Deliver precise, high-tolerance machining for consistent, reliable performance

For silicone rubber rollers, molded parts, and expert roller re-covering, trust a team that understands materials, applications, and performance demands at the highest level.

Let’s Talk Solutions: Get the Right Silicone for Your Application

Need silicone rubber rollers, custom-molded parts, or roller re-covering services? Talk to the experts at Rol-Tec! We’ll match the right materials and engineering approach to your exact specifications.

Contact us today to discuss your needs!

Silicone vs. Nitrile Properties

Rubber Compound |

Nitrile | Silicone | EPDM/Silicone Blends |

| BN | SI | EP/SIL | |

| Physical Properties | |||

| Hardness Range Shore A | 20-95 | 40-90 | 40-95 |

| Hardness Range P&J | 0-200 | 25-185 | 10-140 |

| Abrasion Resistance | 3 | 1 | 3 |

| Tear Resistance | 3 | 1 | 2 |

| Load Bearing | 4 | 1 | 2 |

| Hysteresis | 2 | 5 | 3 |

| Resistance to Denting | 3 | 5 | 3 |

| Maximum Service Temperature (C/F) | 121/250 | 260/500 | 185/365 |

| Ozone Resistance | 1 | 5 | 5 |

| Resiliency | 3 | 1 | 4 |

| Solvent Resistance | |||

| Acids | 2 | 4 | 4 |

| Caustics | 3 | 4 | 4 |

| Paraffinic Hydrocarbons | 5 | 2 | 1 |

| Aromatic Hydrocarbons | 3 | 3 | 2 |

| Chlorinated Hydrocarbons | 1 | 3 | 2 |

| Water | 4 | 4 | 4 |

| Ketones | 2 | 3 | 5 |

| Alcohols | 5 | 4 | 4 |

| Esters | 1 | 3 | 3 |

| Recommended Applications | |||

| Coating/Varnishing | ● | ||

| Embossing | ● | ● | |

| Flexography | ● | ||

| Laminating | ● | ● | ● |

| Laser Engraving | |||

| Metal Decorating | ● | ||

| Offset Printing | |||

| Paper Making Industry | ● | ||

| Plastics | ● | ● | |

| Plate Processors | ● | ||

| Steel Mill Rollers | ● | ||

| Textile Rollers | |||

| Wood Industry | ● | ● | ● |