Laser Engraving

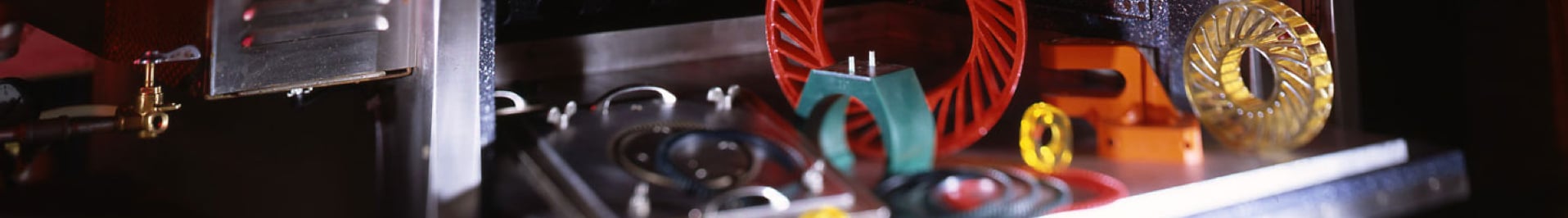

Rol-Tec has launched the newest direct laser technology to cut the highest quality laser engraved rollers and sleeves possible. "In the Round Technology" can now compete with the detail quality of photo polymer sleeves used in the flexographic printing process while lasting much longer. Our newest lasers produce the sharpest dot and the best images available.

What is the advantage of the newest laser system?

- We have direct .pdf to laser technology where we import a supplied high-resolution pdf. of your artwork directly to the Rol-Tec laser system. This reduces or eliminates mistakes as well as upfront artwork costs. If you are paying art charges or set up costs to your laser engraver, try Rol-Tec to reduce these fees.

- Our lasers have the technology to form the dot specifically for your needs. Dot shaping allows us to manipulate the angles of the side walls to strengthen a particular set of dots, choose the height of each dot, and flatten or round the dot tops to help sharpen your impression. This technology is beneficial to companies in the embossing or flexographic printing industries to help perfect their finished product. We have the ability to cut screens up to 150 lines per inch. Please see the article about our superior laser capability in the October, 2018 Flexo Magazine.

- We have formulated and tested new laser engravable compounds specifically designed for flexographic printing. When our high tech laser technology is combined with the latest polymer compounds, the results are print sleeves and rollers that have proven superior to any other laser engraving available.

- Laser machine size capability to engrave from 2.36” to 15.750” diameter, face lengths to 126” and weight up to 2200 lbs.

The combination of dpi quality, lower setup costs, superior rubber compounds, and years of expertise makes Rol-Tec the best choice for your engraving needs.

Rol-Tec is the only company that controls the entire process from producing the sleeve, to rubber covering, grinding to a print quality finish, and final laser engraving. This allows us to have the shortest lead time in the business while saving art costs and expensive freight charges between sleeve company, rubber coverer, and laser engraver. By manufacturing each component, we are the only company that has the ability to control the quality standards of the entire operation from start to finish.

Any print application in the flexible packaging industry should consider laser engraved sleeves to improve quality and lifespan. Results with water, solvent, and UV ink systems have proven superior with "In the Round Technology" using Rol-Tec laser engraved sleeves.