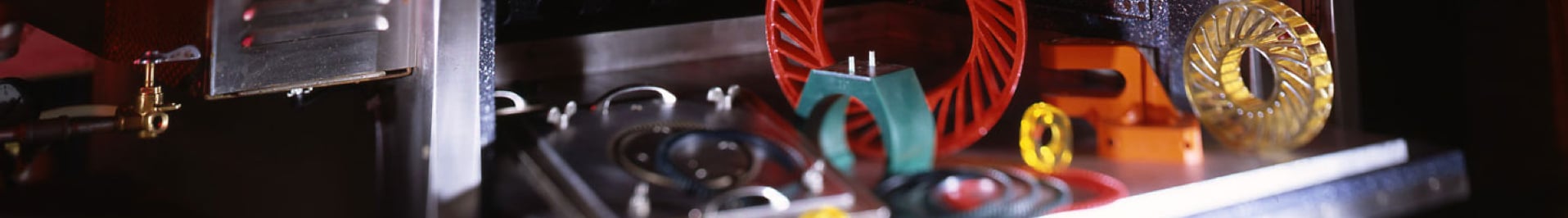

In addition to being a trusted supplier of new industrial rollers & cores, Rol-Tec specializes in rubber and urethane roller recovering services. Whatever the application or wear, we can give your roller new life by replacing the old cover with new rubber or cast urethane. The new cover specifications will meet or exceed the highest industry standards for a new rubber roller.

Types of Rollers and Materials

We can recover just about any roller that falls within our machine size limitations of 31” OD x 280” between centers. With our extensive inventory of materials, high-tech equipment, and skilled personnel, all repairs and manufacturing are done in one location; reducing costs, saving time, and ensuring the Rol-Tec quality standards for your finished rubber roller.

Recover Materials include:

- Buna-Nitrile

- Hypalon

- Neoprene

- Laser Compounds

- Hydrogenated Nitrile (HNBR)

- Carboxilated Nitrile

- EPDM

- Natural Rubber

- Silicone

- Fluoroelastomers

- Urethane

- Specialty blends, and many more

Our Process

When you send your old rollers to Rol-Tec, our experienced team will complete a full inspection in order to determine the process needed to renew your roller.

Oftentimes it's possible to simply regrind or “kiss grind” the cover if the roller is still in acceptable shape and the customer’s machinery limitations allow. A regrind can save both time and money for both cast urethane and rubber coverings. In order to regrind a cover, we use our precision grinding machines and years of expertise to ensure a roller that will perform like new.

When covers have severe damage or are below their bottom diameter, we will do a complete removal of the old rubber and replace it with an entirely new elastomer cover.

From dynamic roll balancing and metalized plasma coating to reverse engineering capabilities, Rol-Tec can handle any of your roller needs.

When to Recover vs. Replace Rollers

The Rol-Tec team will assess the damage to your roller and take only the necessary steps for repair, leaving you with a like-new roller for a fraction of the cost.

If the cover cannot be re-worked (due to wear or damage), we will completely replace it with a new cover whether the roller needs cast urethane or a blended rubber cover.

As part of our roller recovering services, we will repair the core if damaged. We will machine bores and journals, dynamically balance or reverse engineer to make an entirely new roller when the roll is beyond repair. Our trusted team with decades of experience knows when your industrial rollers are beyond recovering. We will then advise and assist you in the process of complete core and cover replacement.

Companies trust us with their urethane and rubber roller recovering needs because we are invested in providing our customers with the highest quality rollers and covers in the industry. Whatever the demand, Rol-Tec has the staff, the equipment, and the expertise to get your rollers back in business. When you send a roller in to Rol-Tec, you can trust that it is in good hands; rollers and covers are what we do!