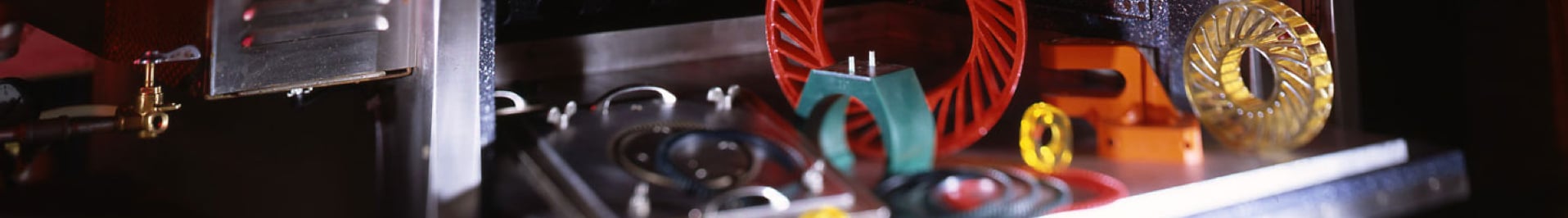

Natural Rubber Parts

Natural Rubber is made from the latex sap of rubber trees from Thailand and other tropical countries. The vulcanization or curing of natural rubber was discovered by Charles Goodyear in 1839, and natural rubber is still used today because it possesses excellent properties beneficial to industry. During World War I, the supply of natural rubber was threatened or eliminated so alternative rubber sources were sought to replace the scarce natural tree gum material. Synthetic elastomers were developed in response to replace this limited natural supply.

While synthetic elastomers are used in the majority of rubber applications today due to their consistency, reliability, and targeted physical properties, natural rubber is still used across the industrial spectrum. Natural rubber is a very tough material that is well-suited for many printing and industrial applications.

Natural Rubber is resistant to denting and tear but will not tolerate exposure to oil or ozone. It can be difficult to process because, like any crop, the natural base latex material can be inconsistent from year to year.

Contact Us to see if Natural Rubber is the right compound for your application.

Natural Rubber vs. Nitrile Properties

Rubber Compound |

Nitrile | Natural Rubber |

| BN | NR | |

| Physical Properties | ||

| Hardness Range Shore A | 20-95 | 25-99 |

| Hardness Range P&J | 0-200 | 5/250 |

| Abrasion Resistance | 3 | 5 |

| Tear Resistance | 3 | 5 |

| Load Bearing | 4 | 5 |

| Hysteresis | 2 | 5 |

| Resistance to Denting | 3 | 5 |

| Maximum Service Temperature (C/F) | 121/250 | 100/212 |

| Ozone Resistance | 1 | 1 |

| Resiliency | 3 | 5 |

| Solvent Resistance | ||

| Acids | 2 | 3 |

| Caustics | 3 | 3 |

| Paraffinic Hydrocarbons | 5 | 1 |

| Aromatic Hydrocarbons | 3 | 1 |

| Chlorinated Hydrocarbons | 1 | 1 |

| Water | 4 | 5 |

| Ketones | 2 | 5 |

| Alcohols | 5 | 5 |

| Esters | 1 | 5 |

| Recommended Applications | ||

| Coating/Varnishing | ● | |

| Embossing | ||

| Flexography | ● | ● |

| Laminating | ● | |

| Laser Engraving | ● | |

| Metal Decorating | ● | |

| Offset Printing | ||

| Paper Making Industry | ● | ● |

| Plastics | ||

| Plate Processors | ● | |

| Steel Mill Rollers | ● | ● |

| Textile Rollers | ||

| Wood Industry | ● |