Machine Shop

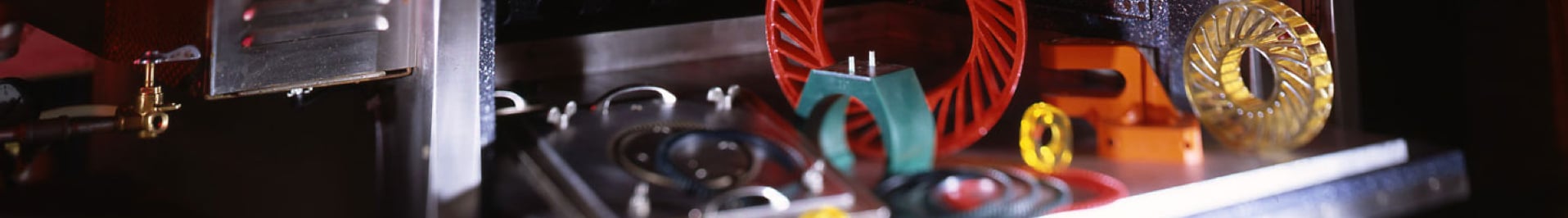

Most elastomer covering companies outsource their machine shop, core repair, and mold making operations. At Rol-Tec, we have an inhouse machine shop to control the entire operation from journal and bore repair to mold manufacturing. We built our machine shop to dramatically shorten lead times and to ensure you receive the best quality rollers built the right way.

We are the roller experts so we know how to design and properly machine roller cores for optimal performance. A correctly designed and constructed roller will perform better in your manufacturing operation and reduce bearing wear.

In house, we repair damaged roller bores and journals, fabricate new cores, dynamically balance, and manufacture the tooling required for our molding and sleeve operations. We can reverse engineer or make a drawing from your existing roller to manufacture a replacement roller. Since no one knows rollers better than we do, we manufacture the best cores and repair them completely to Rol-Tec quality standards. We employ CNC turning centers, CNC vertical milling centers, CNC/manual hybrid lathes, CNC/manual mills, dynamic roll balancers, as well as a variety of other manual machines.

Services Offered:

- Bore and journal repair

- New core fabrication

- Dynamic balancing

- Reverse engineering to construct spare rollers

- Sleeve mandrels

- Mold design and manufacture

Rol-Tec dynamically or statically balances rollers from 2" to 50" OD and face lengths to 260".