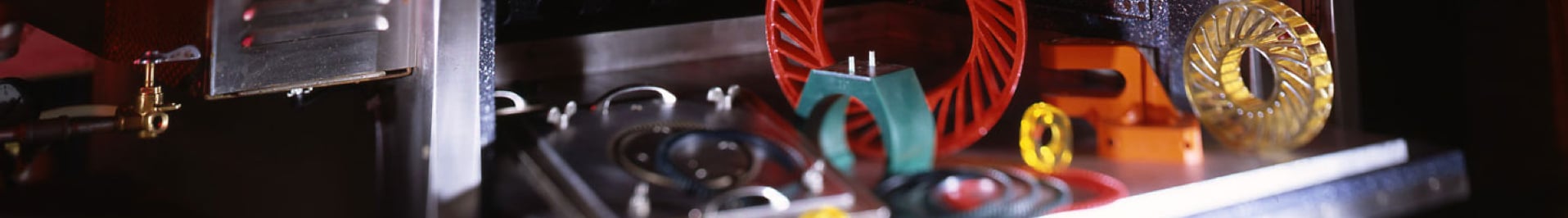

The Industry’s Most Advanced EPDM Rollers & Molded Parts

Rol-Tec operates the highest-tech roller facility of its kind in the world—a fully integrated manufacturing and recovering operation that ensures superior quality, unmatched precision, and industry-leading performance. We specialize in EPDM rubber rollers, molded parts, and rubber roller re-covering services, providing customized EPDM products designed for durability, chemical resistance, and high-temperature applications.

Whether you need new EPDM molded parts, rubber rollers, or expert rubber roller re-covering services, Rol-Tec delivers high-performance elastomer solutions to optimize industrial processes and extend equipment lifespan.

EPDM: The Rubber Compound That Outlasts & Outperforms

EPDM (Ethylene Propylene Diene Monomer) is an advanced synthetic rubber compound engineered to perform in harsh environments where traditional rubber fails. Designed for flexibility, chemical resistance, and extreme durability, EPDM outperforms natural rubber in applications requiring:

Key Advantages of EPDM:

- Superior Chemical Resistance – Withstands acids, alkalis, and solvents, making it ideal for coating, laminating, and industrial processing.

- Exceptional Heat & Ozone Tolerance – Maintains structural integrity in high-temperature and UV-exposed environments.

- Non-Marking & Excellent Release Properties – Reduces surface adhesion, crucial for printing, packaging, and material transfer.

- Customizable Formulations – Blended with Teflon and Silicone to enhance anti-static properties, abrasion resistance, and heat stability.

Rol-Tec EPDM rubber rollers and molded parts are engineered to deliver consistent performance and extended service life, even under the most extreme operating conditions.

EPDM Roller Recovering: Extend the Life of Your EPDM Rollers

Replacing rollers prematurely is costly. EPDM roller recovering restores worn EPDM rollers to like-new condition, extending service life without compromising performance.

Rol-Tec’s EPDM Roller Recovering Process:

- Core Inspection & Surface Analysis – Identify wear and determine optimal recovering solutions.

- Precision Re-Covering – Apply high-quality EPDM compounds that match or exceed original specifications.

- Precision Grinding & Finishing – Achieve perfect surface profiles for optimal roller function.

Recovered rollers perform equal to or better than new, making roller recovering an efficient, cost-effective solution.

High-Performance Rollers for High-Demand Industries

EPDM rubber rollers are at the center of many industrial processes, requiring precision, consistency, and durability to maintain high-performance production. Rol-Tec designs and manufactures EPDM-coated rollers that provide:

Designed for Demanding Applications:

- Flexographic Printing – Optimized for UV ink handling, consistent ink transfer, and non-marking performance.

- Coating & Laminating – Engineered for precise material application without streaking or contamination.

- High-Heat Processing – Formulated for thermal stability in extreme temperature environments.

- Laser Engraving – Maintains ozone resistance and dimensional accuracy for intricate engraving applications.

Why Choose Rol-Tec for EPDM Rollers?

As a trusted supplier of new industrial EPDM rollers & cores, Rol-Tec ensures that every roller meets or exceeds OEM specifications for superior performance and longevity. We offer:

- Precision Surface Finishing – Customizable crowned, grooved, or smooth roller profiles.

- Industry-Leading Quality – Every roller is engineered and finished to the highest industry standards.

- Manufactured in the World’s Most Advanced Roller Facility – No outsourcing, no delays—all production is completed in-house for maximum precision and reliability.

Contact Rol-Tec for Custom EPDM Rollers & Molded Parts

Whether you need new EPDM rubber rollers, custom-molded components, or professional EPDM roller re-covering, Rol-Tec delivers the highest-quality solutions, built to perform. Call us, visit our Green Bay, WI facility, or request a quote online today! Rol-Tec operates at the cutting edge of roller technology—because precision and performance aren’t optional.

EPDM vs. Nitrile Properties:

Rubber Compound |

Nitrile | EPDM | EPDM/Silicone Blends |

| BN | EPDM | EP/SIL | |

| Physical Properties | |||

| Hardness Range Shore A | 20-95 | 20-95 | 40-95 |

| Hardness Range P&J | 0-200 | 10-300 | 10-140 |

| Abrasion Resistance | 3 | 4 | 3 |

| Tear Resistance | 3 | 3 | 2 |

| Load Bearing | 4 | 3 | 2 |

| Hysteresis | 2 | 2 | 3 |

| Resistance to Denting | 3 | 3 | 3 |

| Maximum Service Temperature (C/F) | 121/250 | 177/350 | 185/365 |

| Ozone Resistance | 1 | 5 | 5 |

| Resiliency | 3 | 4 | 4 |

| Solvent Resistance | |||

| Acids | 2 | 5 | 4 |

| Caustics | 3 | 5 | 4 |

| Paraffinic Hydrocarbons | 5 | 1 | 1 |

| Aromatic Hydrocarbons | 3 | 2 | 2 |

| Chlorinated Hydrocarbons | 1 | 1 | 2 |

| Water | 4 | 5 | 4 |

| Ketones | 2 | 5 | 5 |

| Alcohols | 5 | 5 | 4 |

| Esters | 1 | 5 | 3 |

| Recommended Applications | |||

| Coating/Varnishing | ● | ● | |

| Embossing | ● | ||

| Flexography | ● | ● | |

| Laminating | ● | ● | ● |

| Laser Engraving | ● | ||

| Metal Decorating | ● | ● | |

| Offset Printing | |||

| Paper Making Industry | ● | ||

| Plastics | ● | ||

| Plate Processors | ● | ● | |

| Steel Mill Rollers | ● | ● | |

| Textile Rollers | ● | ||

| Wood Industry | ● | ● | ● |