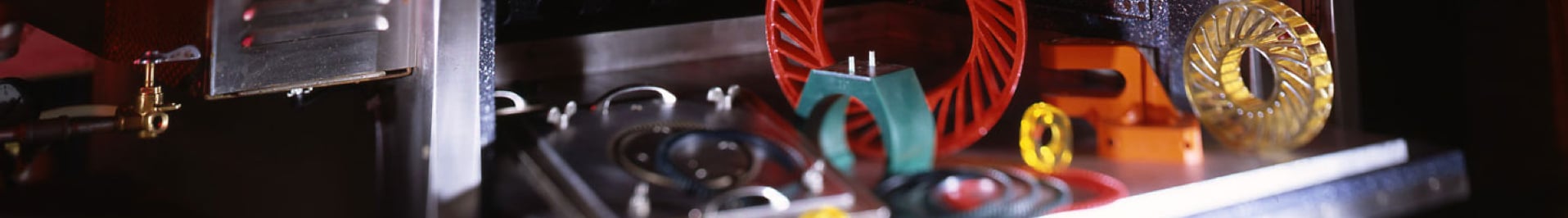

Specialty Rubber Product Blends & Colors

We offer specialty rubber products for the more uncommon applications or demands. We continuously stock industry standard-materials and colors but since elastomers in their raw form have limited shelf life, we may not have certain unusual blends or colors in our inventory. However, we can provide special durometers, colors, or unusual blends if your specifications demand.

Specialty Rubber Product Blends Include:

- Teflon impregnated rubber for greater release

- FDA approved elastomers for aqueous and fatty food contact or food packaging environments

- Anti- static and conductive compounds used to dissipate or eliminate static electrical charges.

- EPDM/Silicone or Hypalon/Silicone blends to achieve specific physical properties.

It is often hard to predict the specific and special needs of our customers. We have the ability to quickly provide a customized special material for your unique need.