Base Sleeve Solutions

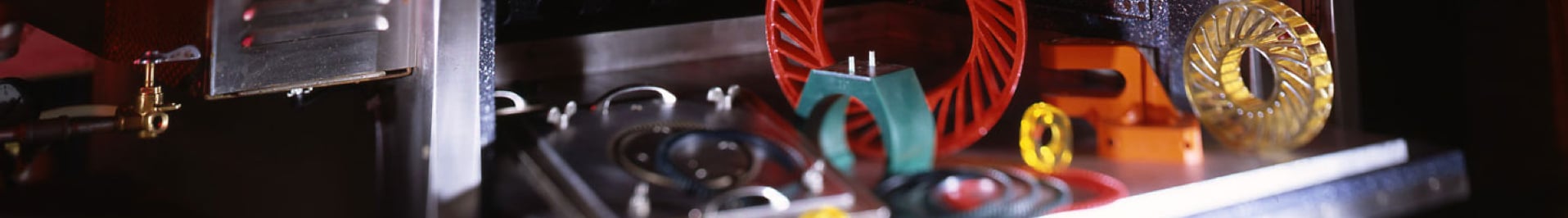

In January 2016, Rol-Tec purchased the best sleeve manufacturing company in the world – Sleeve Solutions LLC. At that time, we moved the manufacturing equipment to our primary facility in Green Bay, WI USA. This move has allowed us to speed the manufacturing process to ship rubber covered and laser engraved sleeves to our customers in the fastest timeframe possible. With all of the work being done in one location, Rol-Tec has eliminated the shipping costs between sleeve supplier and rubber covering company saving the customer hundreds of dollars.

With over 30 years of technology in precision fiberglass sleeve manufacturing, the SLEEVE SOLUTIONS brand offers a wide range of sleeves to fit your exact printing and laminating needs. Our expertise includes tapered and parallel sleeves for rubber and urethane covering. If you are unsure which type of elastomer to use, please call us and we will help you choose the best type of cover for your application.

We also manufacture conductive sleeves to dissipate static charges. When our conductive sleeves are combined with our conductive or anti-static rubber or urethane coverings, you can dissipate static electrical charges. If you wish to alleviate a static charge, the sleeve must be specially designed with conductive material in order to allow any electrical charge to dissipate through the sleeve and ground out through the metal core.

As an alternative to conventional printing plates, the rubber covered sleeves can be laser engraved for a continuous printing pattern. Laser engraving also eliminates the cost of plate mounting. With Rol-Tec’s in-house laser engraving department, all work from the sleeve to the laser engraving is done by one single source. Rol-Tec is the only company in the world that controls the complete sleeve manufacturing, covering and laser process in a single location - start to finish.

For the best system and most exact fit, we manufacture your sleeve mandrels in house. When both the mandrel and the sleeve are manufactured by a single company, a perfect fit is guaranteed. Many OEM’s have seen the logic of the same company manufacturing both the precision mandrel and the base sleeve to insure a perfect fit. This is another reason Rol-Tec is the OEM’s choice as the complete sleeve system supplier.

SLEEVE SOLUTIONS is a trademark of Rol-Tec, Inc.

Parallel base sleeves are made with the same specially designed fiberglass materials as our tapered sleeves to ensure the best structural integrity.

Tapered sleeves are recommended where superior gripping pressure is needed and any sleeve slippage is unacceptable.