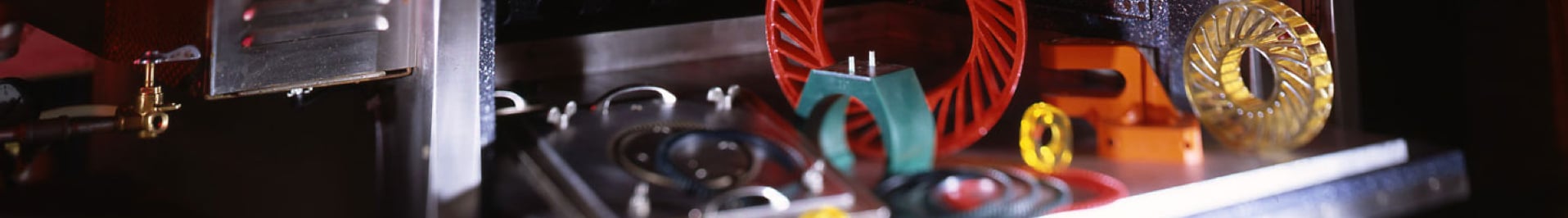

Rubber Covered Rollers

Since 1991, Rol-Tec has become the industry leader in rubber covering and grinding by utilizing the best compounds, equipment, and skilled craftsmen. Our state-of-the-art facility was designed to manufacture rollers in the most efficient way possible to provide the best performing roller covering for your application. From kiss grinds to complete core fabrication, Rol-Tec is the single source for all of your industrial rubber roller needs. Rollers and cores to 31” OD by 280” Face Lengths.

New Rubber Rollers

Here at Rol-Tec we specialize in manufacturing every aspect of your custom molded rubber roller. We have an extremely high-tech facility, with a full machine shop. Our capabilities include dynamic roller balancing, laser engraving, and precision sleeves.The wide range of services offered and our ability to complete projects in house ensures we can control quality from beginning to end.

Rubber Roller Repair

We are all around rollers experts. Our machine shop can repair damages rollers, including the bores and journal. We also offer roller recovering services, meaning we replace the rubber or urethane cover that surrounds the core.

Services Offered:

- Entire new core fabrication and new cover both done in one location. See Machine Shop.

- Journal & bore repair in-house

- Regrind your existing rubber covered roller

- New cover on your customer supplied core

- Completely strip off old used rubber & recover with new elastomer

- Many types of elastomer rubber blends and cast urethane covers formulated to suit your specific application. Ask a Rol-Tec representative for a recommendation or see our materials page.

- Specialty compounds and blends available for the most challenging applications.

- Specialized Grinds, Grooves, and Crowns

Rubber Roller Applications

- Rubber Drive Rollers

- Feed Rollers

- Power Rollers

- Laminator Rollers

- Paper Coating Rollers

- Metering Rollers

- Web Offset Printing Rollers

- Agriculture and Mining

- Building Materials and Manufacturing

- Coating, Laminating, and Varnishing

- Converting and Packaging

- Food Processing

- Military, Weapons, and Sports

- Oil and Gas

- Paper Making

- Poly Manufacturing

- Printing

- Steel and Metal Manufacturing